Building Supply Chain Resilience Against Global Risks

Supply Chain Resilience: Achieving Long-Term Resilience and Agility

Get ahead of your supply chain vulnerability issues.

In 2025, manufacturing supply chains are facing a multitude of disruptions and risks that are reshaping the industry landscape. These challenges are driven by a complex interplay of economic, geopolitical, and environmental factors. Economic pressures, such as rising inflation and operational costs, are squeezing profit margins and forcing manufacturers to rethink their supply chain strategies. Central banks are increasingly focusing on supply chain operations as a potential source of inflation, highlighting the critical role these operations play in the broader economy.

Building Supply Chain Resilience Against Global Risks

Including ongoing conflicts in regions like the Middle East and trade disputes involving essential materials such as semiconductors, are causing significant disruptions. These tensions can lead to supply shortages, increased costs, and delays, making it difficult for manufacturers to maintain steady production schedules.

Including strikes and shortages, are another major challenge. Strikes in key logistics hubs can halt the movement of goods, while labor shortages can slow down production and increase costs. These issues are compounded by the need for skilled workers, particularly in areas requiring digital and technical expertise.

Also on the rise, with climate change-related events such as hurricanes, floods, and droughts becoming more frequent and severe. These events can damage infrastructure, disrupt transportation routes, and lead to supply shortages, further complicating supply chain management.

An ever-present risk. The increasing frequency and sophistication of cyberattacks can lead to significant financial losses, data breaches, and operational disruptions.

Use Technology to Strengthen Supply Chain Resilience

Manufacturers are making significant progress in these areas, but the journey to achieving a fully resilient and agile supply chain is ongoing. Continuous innovation and adaptability are key to navigating the complex landscape of supply chain risks in 2025 and beyond.

Keeping up with technological advancements is crucial for maintaining this agility. The integration of cutting-edge technologies, such as artificial intelligence (AI) and machine learning (ML), is transforming supply chain management. These technologies enable manufacturers to predict disruptions before they occur, optimize logistics, and enhance decision-making processes through data-driven insights. AI and ML can analyze vast amounts of data to identify patterns and trends, allowing for more accurate forecasting and efficient resource allocation.

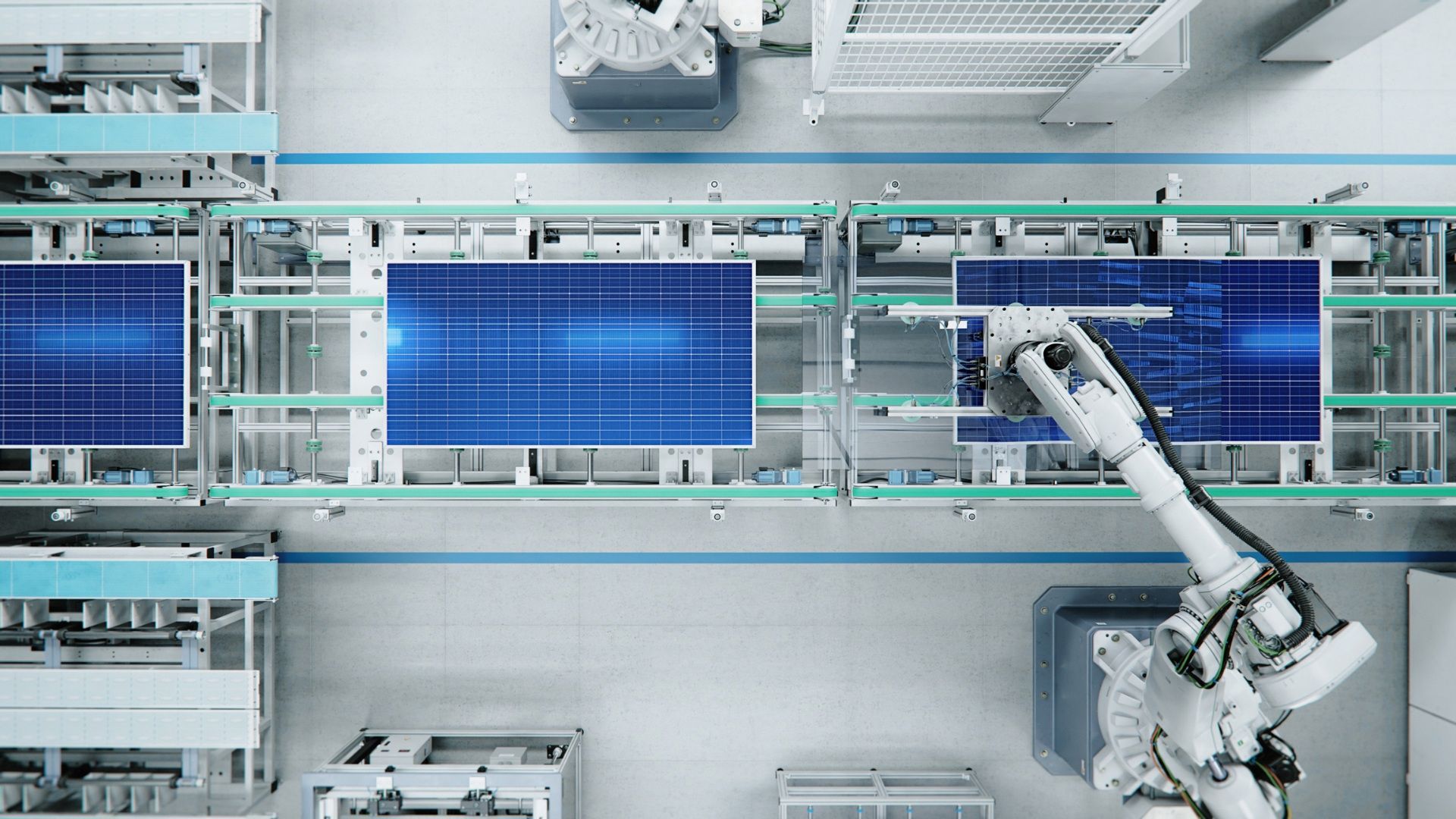

Moreover, advancements in automation and robotics are streamlining operations, reducing human error, and increasing productivity. By automating repetitive tasks, manufacturers can focus on more strategic activities, improving overall efficiency and responsiveness.

Investing in these technologies is crucial for building a resilient supply chain, and it doesn’t have to be prohibitively expensive. Manufacturers are finding innovative ways to overcome resource and cost constraints. By forming collaborative partnerships and utilizing cloud-based platforms, they can deploy scalable and cost-effective technology solutions. These approaches allow manufacturers to access advanced tools and capabilities without significant upfront investments, making it easier to integrate cutting-edge technologies like AI and machine learning into their operations.

As manufacturers continue to embrace these technological advancements, they are better equipped to handle the uncertainties of the future. The ability to quickly adapt to changing conditions, coupled with the strategic use of technology, will be key to achieving long-term resilience and agility in the manufacturing supply chain.

"Our biggest supplier of xenon was the steel works in Mariupol and we witnessed the price of material increase tenfold in a few weeks"

Dynamics 365 Supply Chain Management Overview

Create a more resilient and sustainable supply chain and meet your business and customer commitments profitably.

Read the Manufacturing Agility Assessment

The Manufacturing Agility Report delves into the evolving landscape of manufacturing, highlighting how companies are navigating new obstacles. These challenges stem from changing market conditions, supply chain issues, increasing operational expenses, and ongoing digital transformation.

This year’s analysis focuses on how organisations have enhanced their planning strategies, restructured their supply chains, and committed more to sustainable initiatives.

HSO Supplier Relationship Management Accelerator

The HSO SRM Accelerator is a game-changer for any organisation wanting to streamline and gain full management of their entire supplier lifecycle. Find out how it can help drive profitable business and enhance global supplier engagement.

DIVE INTO

Supply Chain Resiliency Resources

Optimize your supply chain and material requirement planning with demand-driven planning

Explore the latest principles and best practices for supply chain management and where other companies have been successful

DDMRP (Demand-Driven Material Requirements Planning) is the newest iteration of MRP, combining all the best elements from tried and tested manufacturing principles.