DIVE INTO

Supply Chain Resiliency Resources

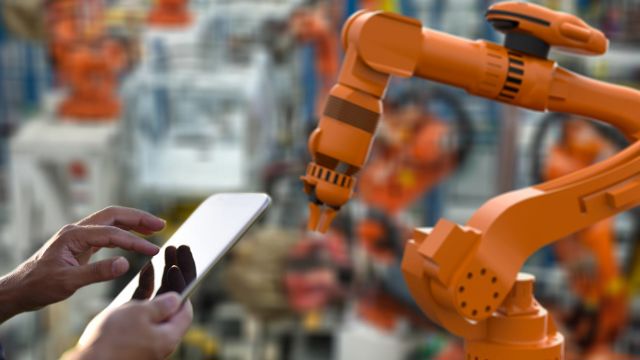

Smart manufacturers find opportunities in supply chain disruption

Get ahead of your supply chain vulnerability issues

This year’s supply chain risks are significant, and the best way to protect yourself is to prepare for the worst and hope for the best. Creating long-term plans with built-in flexibility will give you the best chance for success amid disruption, inflation, increased competition, and more. When the COVID-19 outbreak struck, manufacturing organizations found themselves questioning nearly every aspect of their operations.

Manufacturers of all shapes and sizes mobilized to understand the situation, predict what was coming next and adapt the way they operated in response to what was happening. Manufacturers needed to be agile to cope with the constantly changing dynamics; they had little choice.

Virtually overnight, we saw a raft of changes implemented, including the adoption of digital technologies, revised working practices and new supply chains. This was a lesson in agility itself. We even saw numerous firms temporarily repurposing to produce products they probably wouldn’t have made otherwise such as ventilators, face shields and test kits.

Having implemented a number of changes to rapidly respond to the unfolding situation, many organizations were left with an artificially inflated perception of their agility. Once the dust had begun to settle and there was scope to take stock – particularly by looking at other manufacturers around them -the true level of their agility became apparent.

“If I’m honest, the reason why so many organizations said they were ‘highly’ or ‘extremely’ agile last year is because they genuinely believed they were. Many implemented programmes to counteract the COVID-related chaos and they survived. But in reality, most, including us, thought they were better than they were and, as it happens, we were no more agile than anybody else.”

Read the current industry and economic trends impacting the manufacturing industry

69% of manufacturers are putting their supply chains under the microscope. Are you?

By automating manual processes and properly leveraging the data you have, your organization can start realizing agility gains right away, and with very little in the way of capital investment.

Microsoft Supply Chain Center Demo

Create a more resilient and sustainable supply chain and meet your business and customer commitments profitably.

Read the 2023 Manufacturing Agility Assessment

The 2023 Manufacturing Agility Assessment, the third iteration of its kind, provides a deep dive into the industry’s agility, strategy, challenges and goals.

Discover why manufacturing organisations believe their agility has increased since 2022; the importance of data for decision-making; the obstacles coming between companies and their goals over the next 12-24 months; and why manufacturers are looking to retain first, recruit second. The 2023 Manufacturing Agility Assessment provides an in-depth look into the industry’s agility, strategy, challenges and goals

Register for our live webinar on the November 29th in which we delve into the manufacturing industry's continuing endeavour to become more agile and better prepare for the next big challenge.

DIVE INTO

Supply Chain Resiliency Resources

Optimize your supply chain and material requirement planning with demand-driven planning

Explore the latest principles and best practices for supply chain management and where other companies have been successful

DDMRP (Demand-Driven Material Requirements Planning) is the newest iteration of MRP, combining all the best elements from tried and tested manufacturing principles.