read more

Knowledge and customer cases on Manufacturing

You can build the factory of the future right now

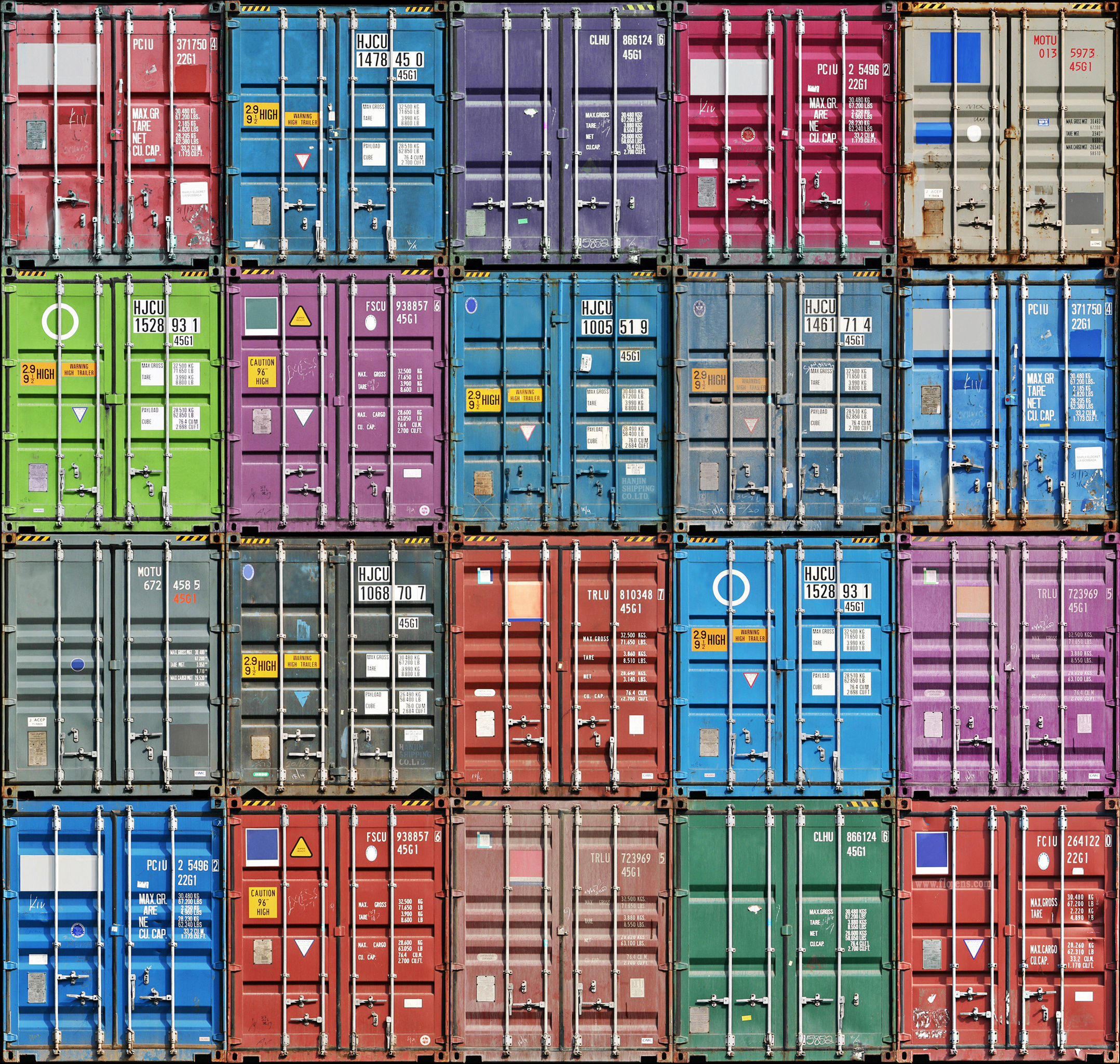

Semiconductors, raw materials, labor: it seems as if the world is running out of everything. For manufactures, these are hard times. Difficulties are compounded by disruptions in the supply chain, all of which are muddying demand forecasts. Who knows how long a product will take to be made and shipped? But there is help on the way for COO’s.

Having supply chain resilience is a competitive advantage. To overcome todays supply chain disruptions a study by McKinsey found that 97% of the organisations boosted the resilience of their supply chains by implementing a combination of inventory increases, dual sourcing, and regionalisation. We have seen that COO’s have rapidly begun to implement supply chain digitisation, but still, are they really in control? There are three key supply chain trends in a good supply chain strategy:

To stay competitive, manufacturers need to build an agile, connected factory that evolves into a complex ecosystem of self-regulating machines that can provide a reliable source of data, providing a seamless interface between the physical and virtual world. With digital twins and digital feedback loops, this self-regulating factory can run realistic simulations of the limits and capabilities of factories, create optimal plans, then monitor and adjust them accordingly.

The Microsoft platform gives organisations the foundation on which to build the factory of the future. The end-to-end solution of Microsoft Dynamics 365 F&SCM, Microsoft Power Platform and Microsoft Azure Services help to securely connect people, assets, workflows, and business processes, empowering organisations to be more resilient.

These solutions form the basis of the Microsoft Cloud for Manufacturing, which depicts connected experiences across the end-to-end product and service lifecycle.

You will also find capabilities in the Microsoft platform like Asset Productivity, Learning and Knowledge Management, Always-on-Service, Supply Chain Visibility, and more. The Microsoft Power Platform solution provides a low-code/no-code platform that boosts the digital transformation in an unprecedented way. Take auditing production lines for example. Instead of paperwork, sending emails and typing data into systems, you can easily and inexpensively build an app for this, often within a day. This allows the supervisor to use his or her smartphone and take a picture, tick some checkboxes, and the data is immediately captured in the central system.

Such apps can reduce communication from days to minutes. In addition, data entry becomes error-free and easily traceable. You get real-time insight into all automated processes. Thanks to the right combination of data and the way this data is analysed, the data becomes actionable and gives organisations a competitive advantage.

Sharing progression In the 30 years I have worked in manufacturing, and the 15 years I have been Industry Director and EMEA Business Solutions Lead for Manufacturing and Automotive, HSO International has always been the partner that would come up as the solution partner of choice. Outstanding implementation, customer care and customer satisfaction are just a few examples of the quality HSO international delivers again and again.

By powering your global end-to-end supply chain, we transform business processes to be more efficient using the full potential of the Microsoft cloud platform. We execute as a single team with no handovers or handoffs, no matter how many borders we need to cross or regulations we need to handle. We utilise our Global Presence and turn it into a true Global Practice.

Feel free to contact us

read more

Knowledge and customer cases on Manufacturing