Read more

Manufacturing AI content

Facing soaring product recall costs and stricter quality standards, manufacturers are turning to AI for manufacturing quality control to elevate their inspection processes to the next level.

Product quality, safety and reliability have always been fundamental principles in manufacturing. From the earliest days of craftmanship to the advanced technologies of today, ensuring that products meet quality standards and pose no risk to consumers has been a constant priority.

Yet, the pressure on manufacturers to deliver goods to exacting standards is growing due to increased regulatory scrutiny, higher consumer expectations, stiff global competition and greater product complexity.

The cost of poor product quality is also on the rise. As the price of materials, labour, energy, shipping and losing customers increase, so does the cost of rework, scrappage, warranty claims and recalls. Even the best-performing manufacturers reportedly spend 10 to 15% of total sales revenue on fixing mistakes and managing poor quality issues.

More worrying is the sharp rise in recall incidences. European product recalls hit a 10-year high in 2023, marking the fifth consecutive year that recalls increased. According to the latest European Recall Index, the surge was driven by recalls in the food and drink, medical device, pharmaceutical, electronics and clothing industries.

Even industries with lower recalls in 2023 mask long-term rises. The 727 events in automotive last year may have been down 3.3% in 2022, but it was still the second-highest number recorded in the past decade. 2023 is also the only year on record to have two quarters with more than 200 automotive recall events.

The urgent need for more robust inspection and quality control methods is driving the integration of AI for manufacturing quality control, transforming how companies ensure product integrity, reliability and safety. Such is the pace of adoption that Gartner predicts 50% of manufacturers will rely on AI-driven insights for quality control by 2025.

AI-Powered Quality Inspection

Traditional quality control methods, while effective to a degree, have inherent limitations. Human inspectors, no matter how skilled, can miss subtle defects or inconsistencies, leading to compromised product quality slipping through the cracks.

Manual inspections are also time-consuming and prone to variability, especially with increasing production volumes and product complexity. By harnessing advanced AI algorithms, machine learning and computer vision for manufacturing quality control, manufacturers can achieve a level of accuracy and speed previously unattainable with human or automated methods.

Unmatched Defect Detection

AI excels at analysing vast amounts of data, including visual information, to detect even the smallest flaws or anomalies that might escape human eyes. From microscopic imperfections in electronic components to irregularities in food packaging, AI systems leave no room for oversight. Indeed, studies have shown that AI-based visual inspection can increase defect detection rates by as much as 90% compared to human inspection.

Real-Time Monitoring and Intervention

A significant advantage of AI-powered quality control systems is the ability to monitor production processes in real-time rather than at scheduled intervals or stages. By continuously analysing data streams from sensors and cameras, AI systems can identify anomalies as they occur, enabling immediate intervention and minimising wastage and potential downstream impacts.

How AI is Reshaping Maintenance Strategies to Minimise Downtime

With downtime costs skyrocketing, artificial intelligence is helping prevent unexpected stoppages and propel predictive maintenance into the mainstream.

Predictive Maintenance for Quality Assurance

Just as AI optimises the maintenance of production equipment, it also enhances the reliability of quality control systems in manufacturing. By analysing performance data and detecting early signs of equipment degradation, AI ensures that inspection tools remain accurate and calibrated, contributing to consistent quality control outcomes and reducing the likelihood of false positives or negatives.

More Impactful Decision-Making

The benefits of integrating AI into quality inspection and control procedures extend beyond defect detection. AI-driven quality control helps minimise the risk of safety hazards and ensures compliance with regulatory standards, safeguarding consumers and manufacturers.

Data generated and analysed by AI systems also offer valuable insights into production processes, enabling continuous improvement, optimisation and more informed decision-making.

AI’s ability to analyse historical data alongside real-time information provides deeper insights into long-term trends and patterns in manufacturing processes. This enables production managers to understand how variables interact over time and make strategic adjustments to improve efficiency and quality.

Historical data also serves as a baseline for anomaly detection and root cause analysis, further aiding in identifying areas for improvement and maintaining high-quality standards.

Elevating Automated Quality Processes

While automation has improved and streamlined many inspection processes, AI introduces a higher level of intelligence, adaptability and predictive capability, making it a more comprehensive and effective solution for defect detection.

AI enhances automated inspection tools by providing advanced analysis beyond simple rule-based automation. This allows for more nuanced and intelligent decision-making, especially in handling complex data and scenarios like detecting subtle defects that traditional automated systems typically struggle with.

AI-driven quality control systems can also scale more efficiently with changes in production volume, a critical strength in today’s manufacturing environment. Real-time processing of large data volumes results in faster inspection processes and feedback loops for dynamic production adjustments.

The greatest advantage of AI over automated systems is its ability to learn and adapt through new data and experiences. This continuous learning improves the performance and accuracy of AI algorithms over time, a significant advantage over static automated systems that may need manual adjustment or reprogramming to handle new types of defects.

Moreover, AI models can be trained to minimise false positives (flagging non-defective products as defective) and false negatives (missing actual defects), unlike automated systems. This fine-tuning leads to more accurate results and reduces waste and rework caused by incorrect defect identification.

Embrace Cloud for Scalable Data Management

Integrating AI into inspection and detection processes brings many advantages, yet managing the vast amounts of data generated remains a challenge. AI algorithms rely on large, diverse datasets to effectively train models and make accurate predictions.

Modern quality systems often capture multiple photos of, and increasingly video, each component and assembly process, crucial for thorough analysis and record-keeping. However, many companies overlook the need for robust data storage infrastructure capable of handling large volumes and complexity.

Moving to cloud-based solutions offers significant benefits. Cloud platforms provide scalable storage and processing options, accommodating the growing data needs of manufacturers. Unlike on-premise systems, cloud environments ensure real-time data access and analysis, essential for in-process monitoring and swift decision-making.

Additionally, cloud platforms offer secure, long-term storage for historical records, supporting traceability, compliance and continuous improvement initiatives. By migrating to the cloud, manufacturers can enhance data quality, strengthen security measures and improve overall accessibility.

With an adequate data infrastructure in place, the advantage of AI-driven inspection and defect detection becomes clear. As illustrated by the following case studies.

Two Real-World Examples of AI Transforming Manufacturing Quality Control

These real-world examples underscore the transformative power of AI for manufacturing quality control in ensuring the highest standards of product integrity.

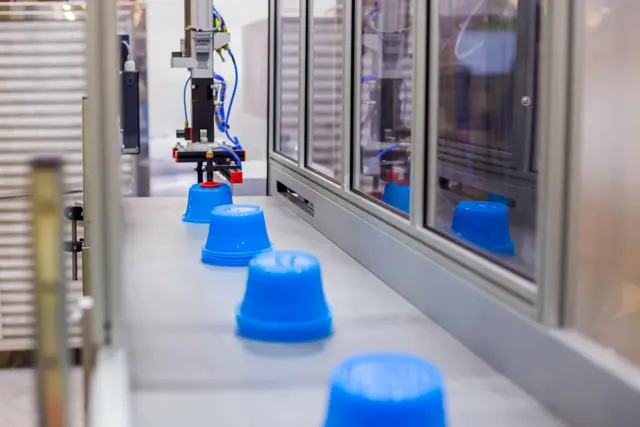

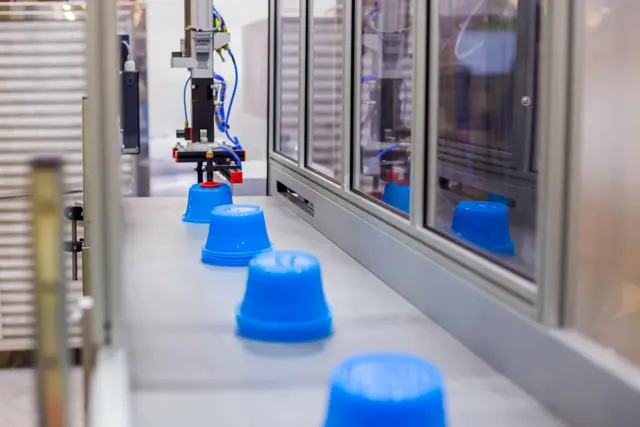

A leading ice cream manufacturer with a global customer base has leveraged AI for manufacturing quality control with an AI-powered vision system to detect production anomalies. The goal is to ensure consistent high quality by spotting and addressing issues related to product appearance, packaging and manufacturing processes.

Using Azure AI Vision Services, the system uses advanced computer vision and machine learning to identify irregularities or unusual patterns in images or videos of ice cream production. The solution classifies products as damaged, undamaged or recyclable, helping maintain manufacturing efficiency and product quality.

BMW Group’s adoption of AI

for manufacturing quality control is evident in their use of automated image recognition, where AI compares images of components during production with hundreds of other images in milliseconds.

This real-time assessment helps detect deviations from the norm and ensures all parts are present and correctly mounted. BMW notes that flexible and cost-effective AI-based applications are steadily replacing fixed camera portals. Employees take pictures of the component from different angles using a mobile standard camera, marking potential deviations directly on the image. This database of images is used to build a neural network that is taught to evaluate the images without human intervention.

Over the past decade, Intel has introduced a range of automated

AI-based solutions aimed at significantly reducing waste and improving product quality.

The company recently integrated computer vision and machine learning into its chip fabrication lines to create an in-line inspection system. In-line inspection allows defects and tool issues to be caught much earlier than traditional off-line inspection processes.

The system can detect micrometre-sized defects that are hard to see even with a microscope. High-resolution cameras take multiple images per second while a grinding tool thins the wafer, and a protective polyester film is installed. These images are analysed at the edge using a machine-learning model.

If defects are detected, the system can trigger an alarm or even stop the tool. Intel says the scrap avoided thanks to the system could potentially save up to $2m each year.

The advancements in AI for manufacturing quality control are not just a futuristic concept but a present-day reality, as demonstrated by the examples mentioned.

If you're looking to revolutionise your manufacturing processes with AI, HSO is here to guide you every step of the way. Our expertise in implementing AI can help you harness the power of cutting-edge Microsoft Dynamics 365 and CoPilot AI technology to enhance product quality, increase efficiency, and reduce costs.

Contact HSO today to discover how we can tailor AI solutions to fit your unique manufacturing needs and set new benchmarks for quality and reliability in your industry.

Read more

Manufacturing AI content

We, and third parties, use cookies on our website. We use cookies to keep statistics, to save your preferences, but also for marketing purposes (for example, tailoring advertisements). By clicking on 'Settings' you can read more about our cookies and adjust your preferences. By clicking 'Accept all', you agree to the use of all cookies as described in our privacy and cookie policy.

Purpose

This cookie is used to store your preferences regarding cookies. The history is stored in your local storage.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

These cookies are stored to keep you logged into the website.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

This cookie is used to submit forms to us in a safe way.

Cookies

Location of Processing

European Union

Technologies Used

Cookies

Expiration date

1 year

Why required?

Required web technologies and cookies make our website technically accessible to and usable for you. This applies to essential base functionalities such as navigation on the website, correct display in your internet browser or requesting your consent. Without these web technologies and cookies our website does not work.

Purpose

This service provided by Google is used to load specific tags (or trackers) based on your preferences and location.

Why required?

This web technology enables us to insert tags based on your preferences. It is required but adheres to your settings and will not load any tags if you do not consent to them.

Purpose

This cookie is used to store your preferences regarding language.

Cookies

Why required?

We use your browser language to determine which language to show on our website. When you change the default language, this cookie makes sure your language preference is persistent.

Purpose

This service is used to track anonymized analytics on the HSO.com application. We find it very important that your privacy is protected. Therefore, we collect and store this data anonymously on our own servers. This cookie helps us collect data from HSO.com so that we can improve the website. Examples of this are: it allows us to track engagement by page, measuring various events like scroll-depth, time on page and clicks.

Cookie

Purpose

With your consent, this website will load Google Analytics to track behavior across the site.

Cookies

Purpose

With your consent, this website will load the Google Advertising tag which enables HSO to report user activity from HSO.com to Google. This enables HSO to track conversions and create remarketing lists based on user activity on HSO.com.

Possible cookies

Please refer to the below page for an updated view of all possible cookies that the Google Ads tag may set.

Cookie information for Google's ad products (safety.google)

Technologies Used

Cookies

Purpose

With your consent, we use IPGeoLocation to retrieve a country code based on your IP address. We use this service to be able to trigger the right web technologies for the right people.

Purpose

With your consent, we use Leadfeeder to identify companies by their IP-addresses. Leadfeeder automatically filters out all users visiting from residential IP addresses and ISPs. All visit data is aggregated on the company level.

Cookies

Purpose

With your consent, this website will load the LinkedIn Insights tag which enables us to see analytical data on website performance, allows us to build audiences, and use retargeting as an advertising technique. Learn more about LinkedIn cookies here.

Cookies

Purpose

With your consent, this website will load the Microsoft Advertising Universal Event Tracking tag which enables HSO to report user activity from HSO.com to Microsoft Advertising. HSO can then create conversion goals to specify which subset of user actions on the website qualify to be counted as conversions. Similarly, HSO can create remarketing lists based on user activity on HSO.com and Microsoft Advertising matches the list definitions with UET logged user activity to put users into those lists.

Cookies

Technologies Used

Cookies

Purpose

With your consent, this website will load the Microsoft Dynamics 365 Marketing tag which enables HSO to score leads based on your level of interaction with the website. The cookie contains no personal information, but does uniquely identify a specific browser on a specific machine. Learn more about Microsoft Dynamics 365 Marketing cookies here.

Cookies

Technologies Used

Cookies

Purpose

With your consent, we use Spotler to measures more extensive recurring website visits based on IP address and draw up a profile of a visitor.

Cookies

Purpose

With your consent, this website will show videos embedded from Vimeo.

Technologies Used

Cookies

Purpose

With your consent, this website will show videos embedded from Youtube.

Cookies

Technologies Used

Cookies

Purpose

With your consent, this website will load the Meta-pixel tag which enables us to see analytical data on website performance, allows us to build audiences, and use retargeting as an advertising technique through platforms owned by Meta, like Facebook and Instagram. Learn more about Facebook cookies here. You can adjust how ads work for you on Facebook here.

Cookies

Purpose

With your consent, we use LeadInfo to identify companies by their IP-addresses. LeadInfo automatically filters out all users visiting from residential IP addresses and ISPs. These cookies are not shared with third parties under any circumstances.

Cookies

Purpose

With your consent, we use TechTarget to identify companies by their IP address(es).

Cookies

Purpose

With your consent, we use this service provided by uMarketingSuite to run A/B tests across the HSO.com application. A/B testing (also called split testing) is comparing two versions of a web page to learn how we can improve your experience.

Purpose

With your consent, we use this service provided by uMarketingSuite to personalize pages and content across the HSO.com application. Personalization helps us to tailor the website to your specific needs, aiming to improve your experience on HSO.com.

Purpose

With your consent, we use ZoomInfo to identify companies by their IP addresses. The data collected helps us understand which companies are visiting our website, enabling us to target sales and marketing efforts more effectively.

Cookies